P Charts Worksheet

P charts are an essential tool in statistical process control, allowing businesses to monitor and analyze the variation in quality control data. With the help of P charts, organizations can identify and address any deviations from the desired level of performance. If you are a quality control professional or a business owner looking to improve your processes' outcomes, implementing P charts can be a valuable asset for your operations.

Table of Images 👆

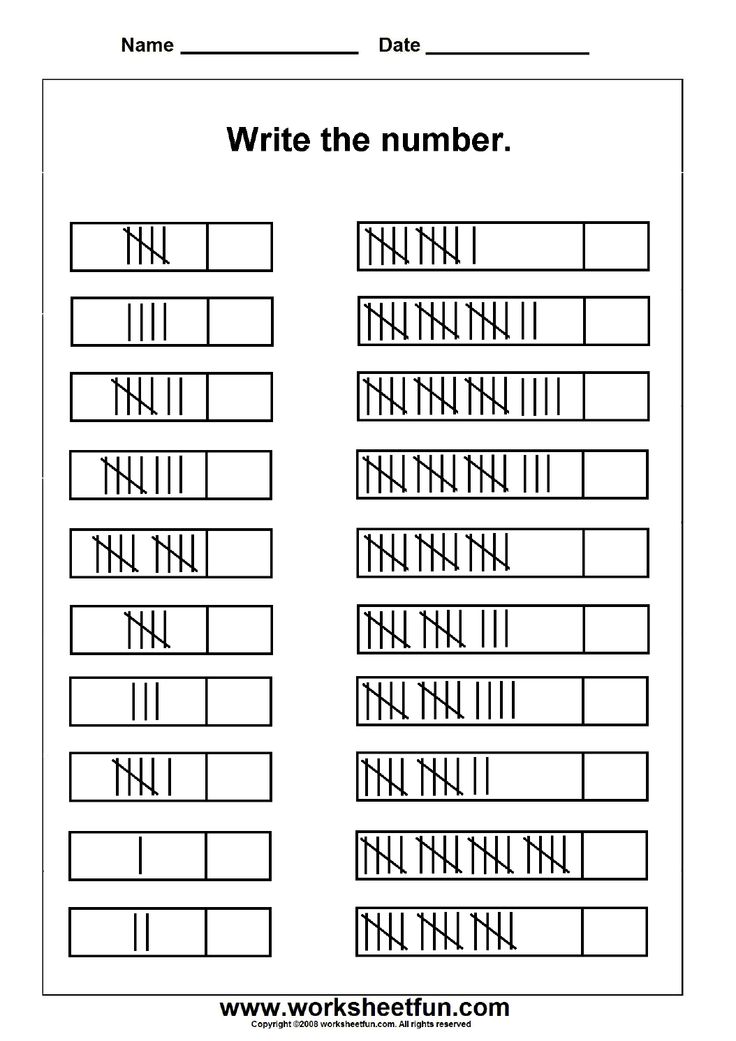

- Printable Tally Mark Worksheets

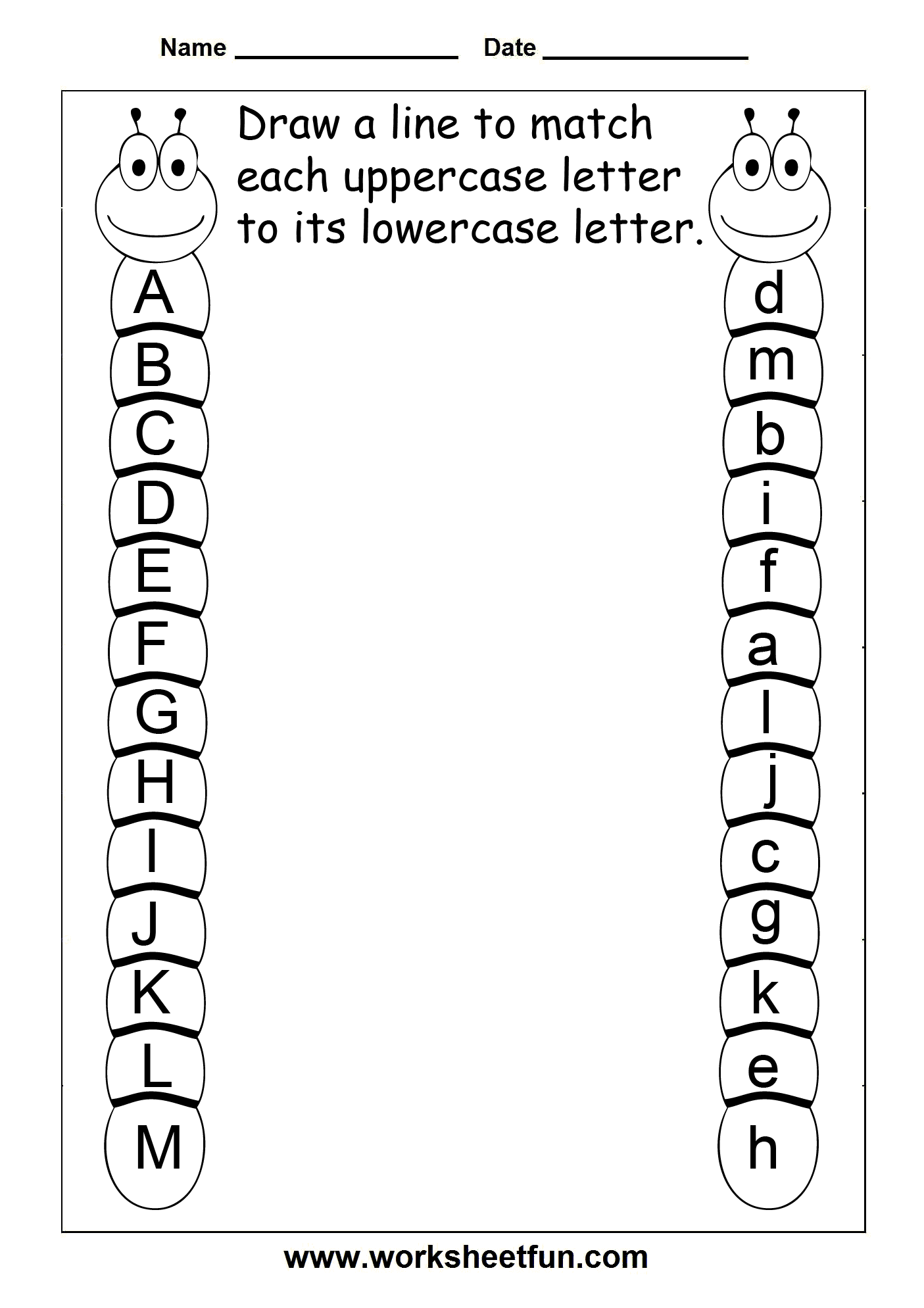

- Uppercase Lowercase Letters Worksheet

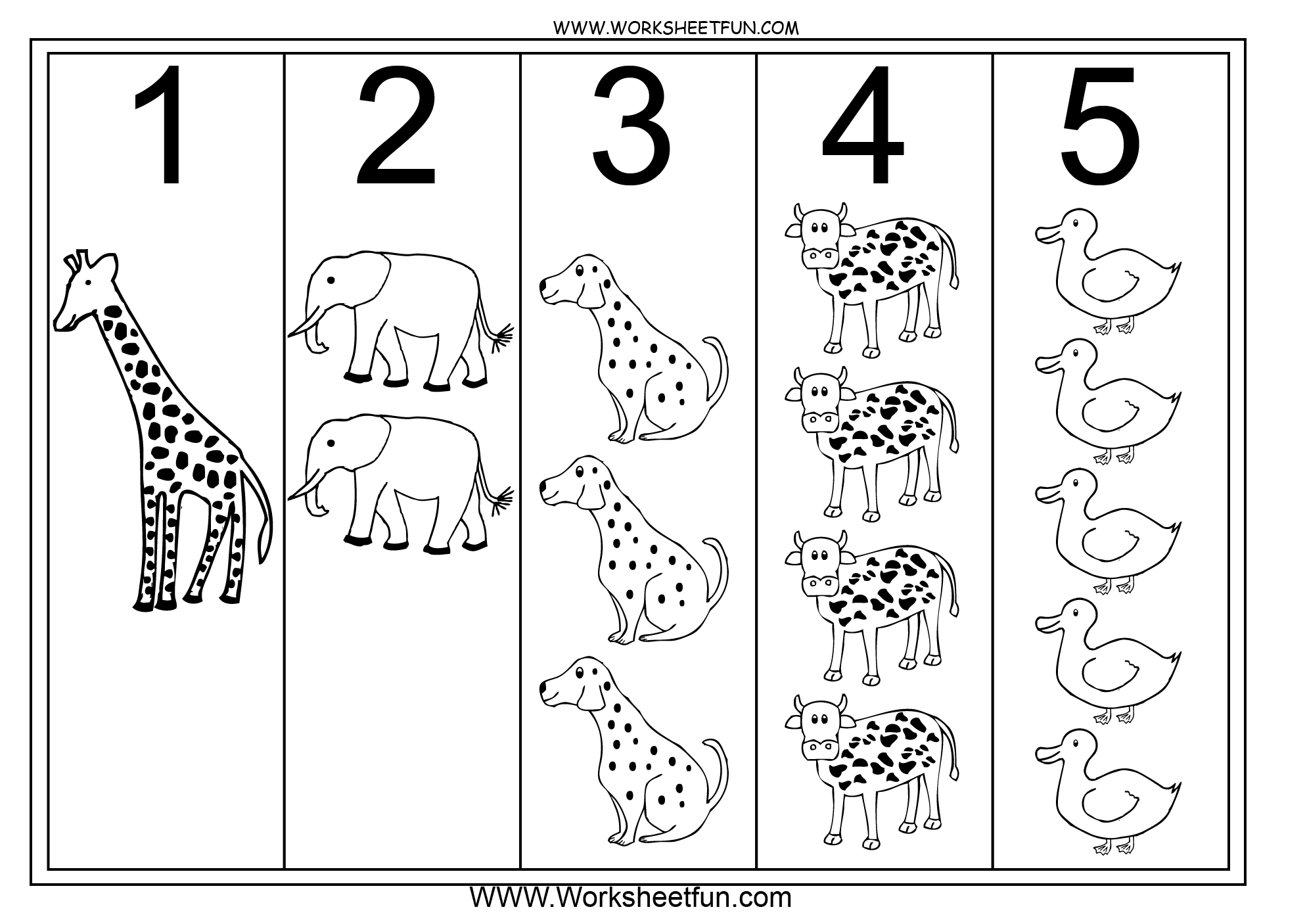

- Preschool Worksheets Numbers 1 5

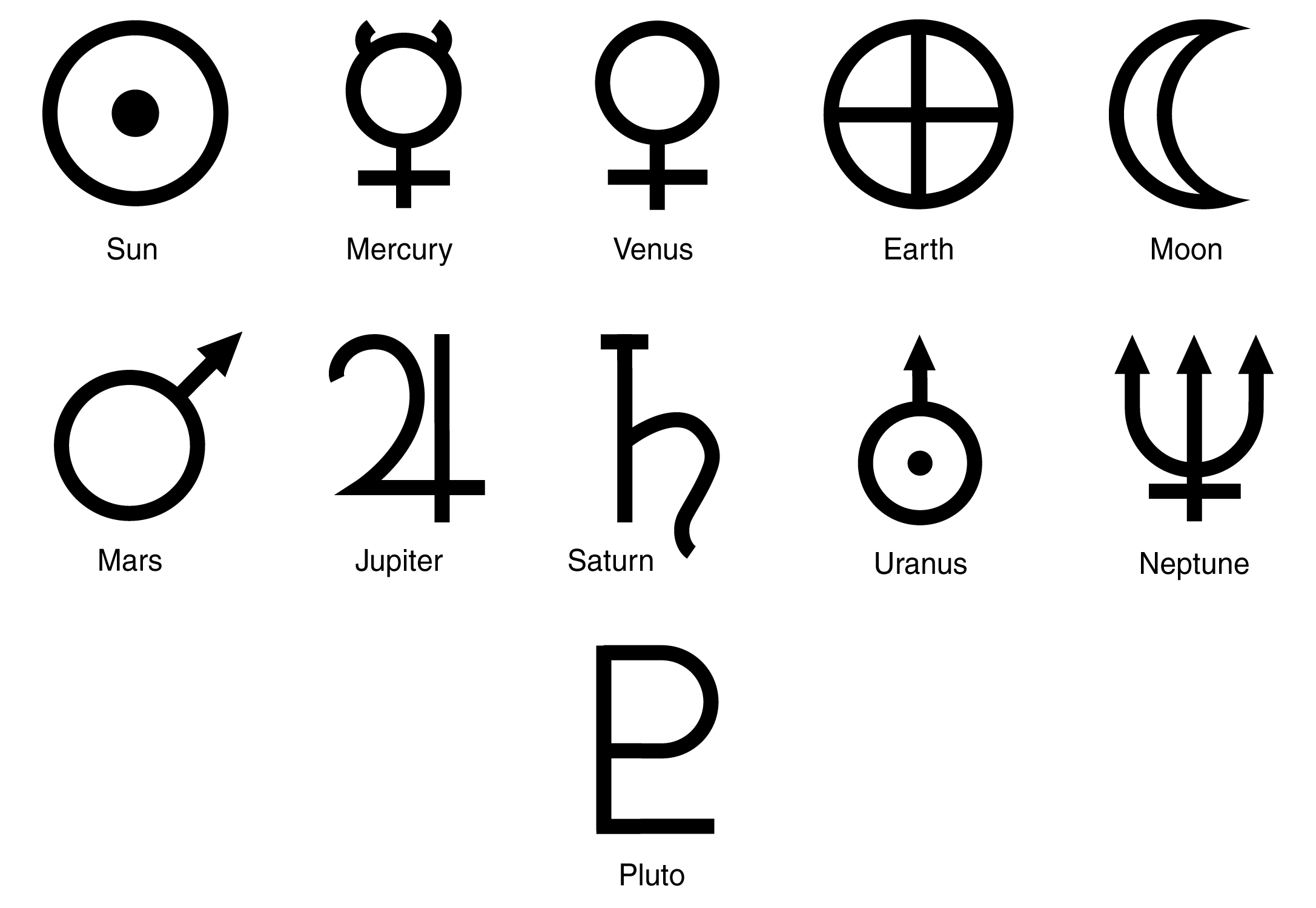

- Greek Planet Symbols

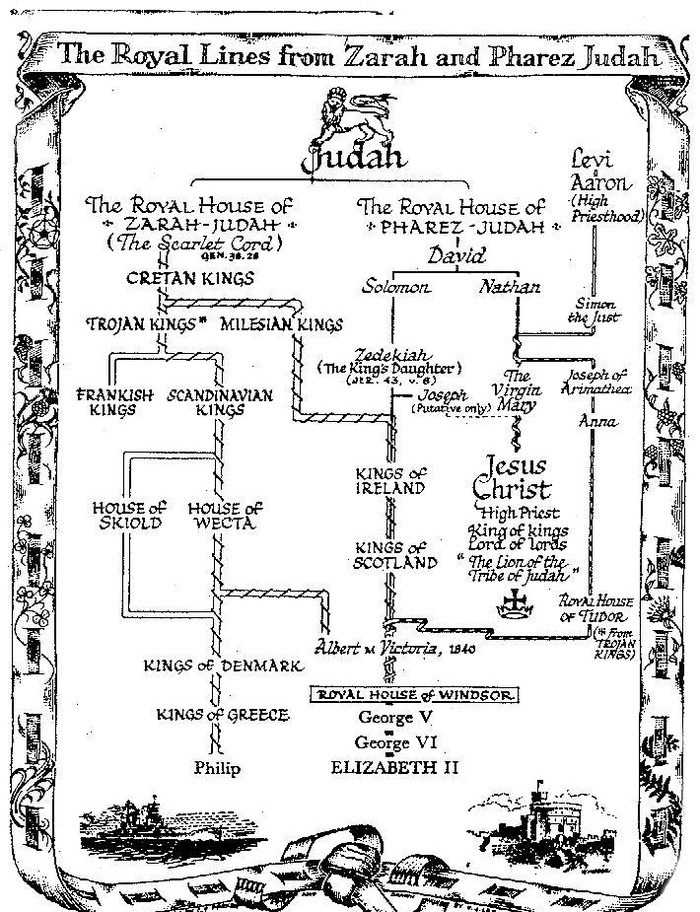

- Queen Elizabeth II Family Tree

- Tangled Coloring Pages

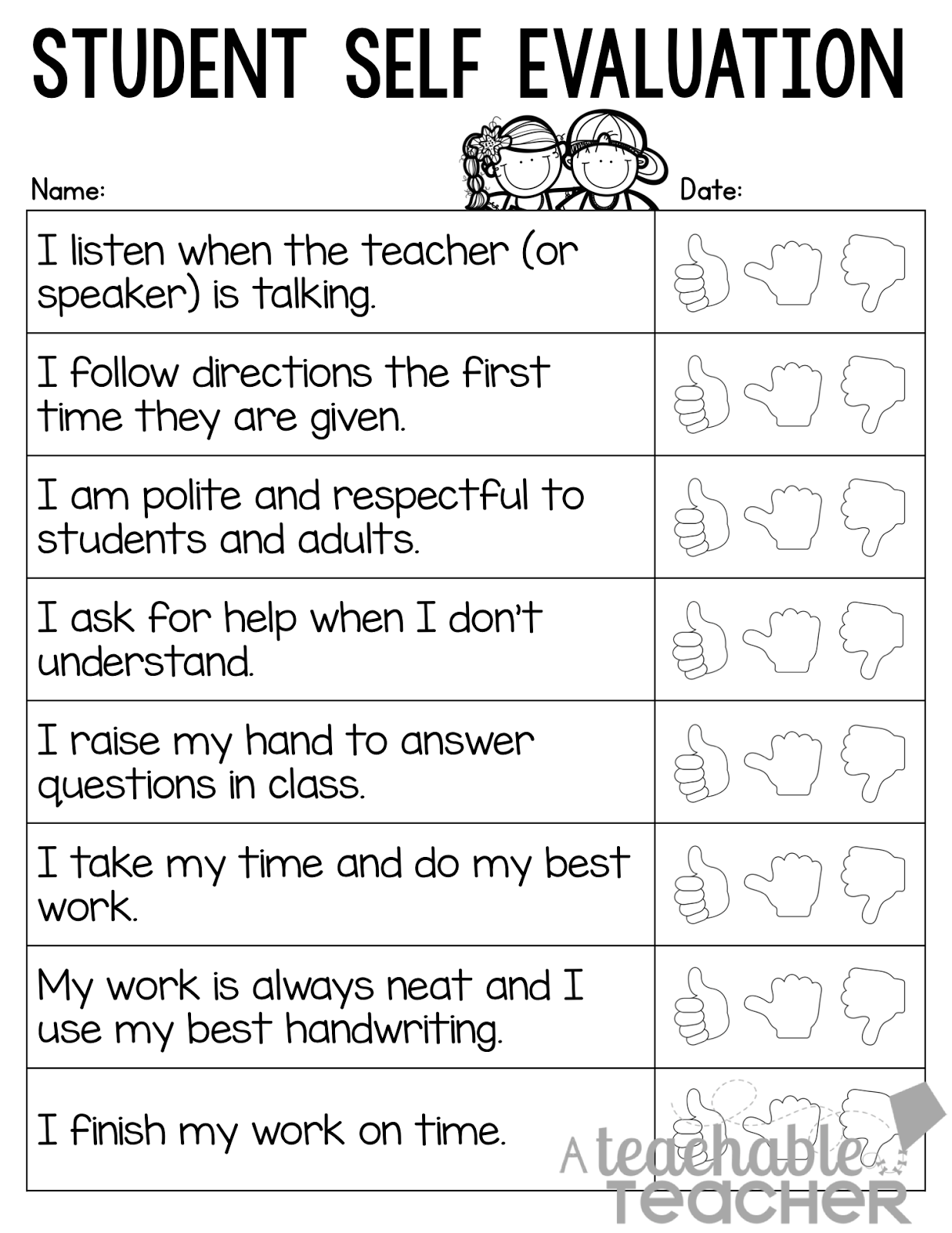

- Student Self Evaluation Form

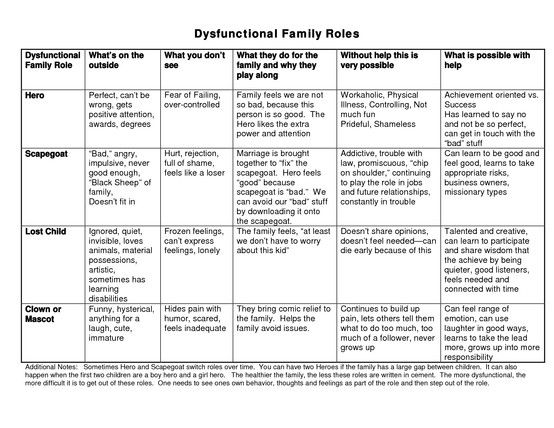

- Dysfunctional Family Roles Chart

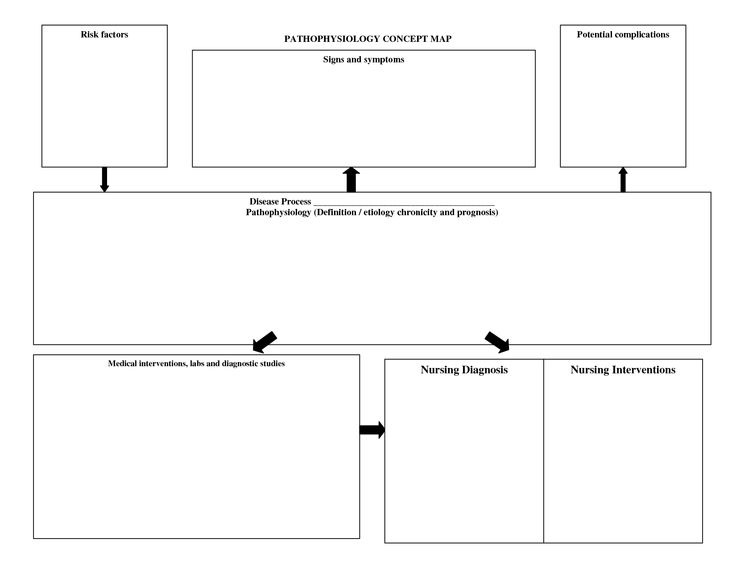

- Nursing Diagnosis Concept Map Template

- Conferences Parent Teacher Student Self-Evaluation Sheets

- Blank Color Wheel

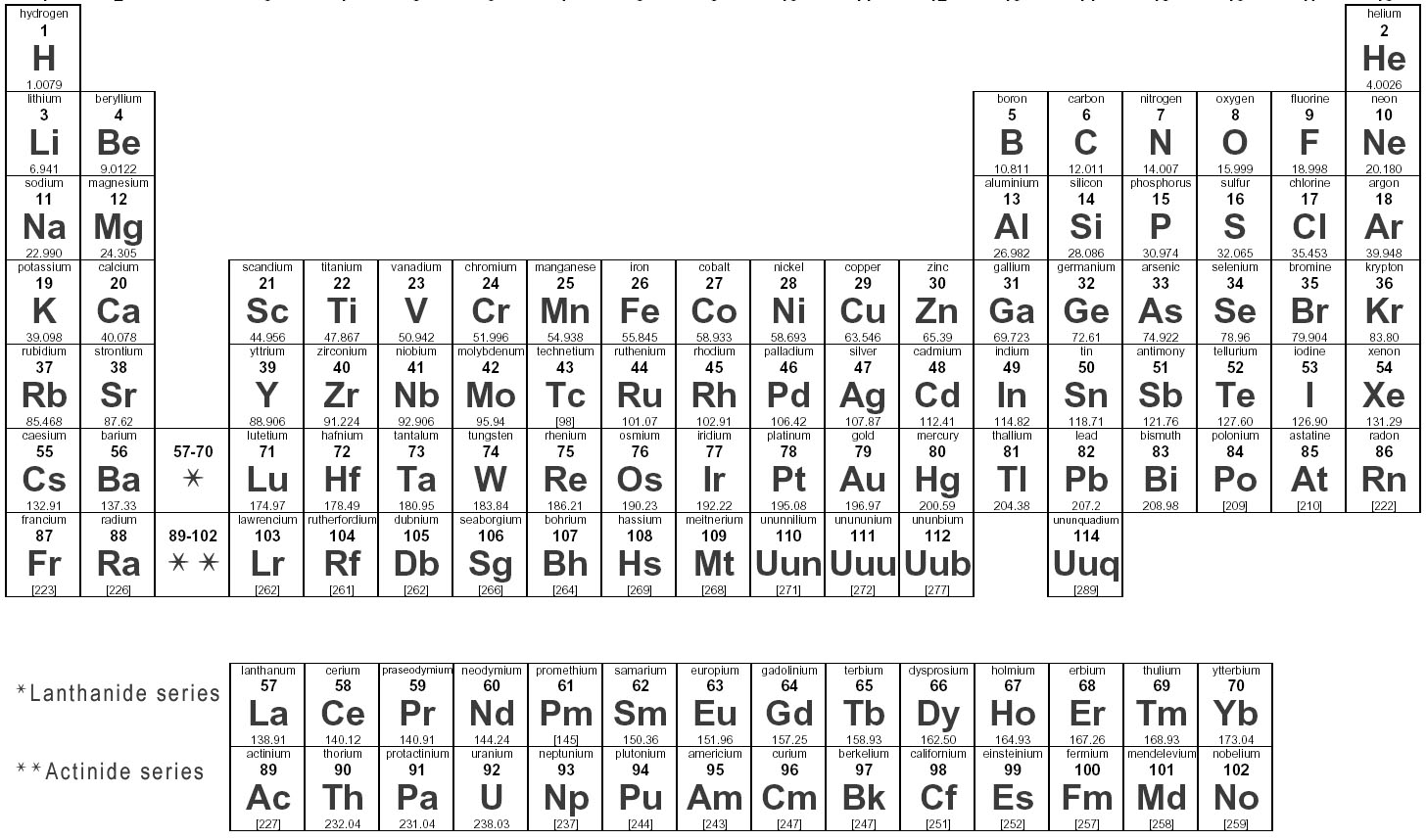

- As Periodic Table of Elements

More Other Worksheets

Kindergarten Worksheet My RoomSpanish Verb Worksheets

Cooking Vocabulary Worksheet

DNA Code Worksheet

Meiosis Worksheet Answer Key

Art Handouts and Worksheets

7 Elements of Art Worksheets

All Amendment Worksheet

Symmetry Art Worksheets

Daily Meal Planning Worksheet

What is a P Chart?

A P Chart is a type of control chart commonly used in statistical process control to monitor the proportion of nonconforming units in a sample. It is particularly useful in tracking the percentage of defective items in a process over time, allowing for early detection of trends or shifts that may indicate a process is out of control.

What is the purpose of a P Chart?

A P Chart is used to monitor the proportion of nonconforming items in a sample or process over time. It helps to identify trends and patterns in the data, making it a useful tool for quality control and process improvement efforts by indicating when corrective actions may be necessary to maintain consistency and quality standards.

What type of data is used in a P Chart?

A P Chart uses attribute data, which consists of countable, discrete values that represent the presence or absence of a particular quality characteristic or attribute in a sample. This type of data is binary in nature, typically denoted as either 1 or 0, and is used to analyze the proportion of nonconforming items in a process over time.

How is the upper control limit (UCL) determined in a P Chart?

The upper control limit (UCL) in a P Chart is determined by calculating the average proportion of nonconforming units in the process being monitored and then adding a multiple of the square root of the average proportion of nonconforming units to the average proportion. The most commonly used multiple is three sigma, which provides a 99.7% confidence level that the process is in statistical control. This UCL value helps in determining if the process is operating within acceptable limits and if any action needs to be taken to address variations in the process.

How is the lower control limit (LCL) determined in a P Chart?

The lower control limit (LCL) in a P Chart is typically calculated using statistical formulas based on the process average and the inherent variability of the process being monitored. It is derived by multiplying the standard deviation of the sample proportion by an appropriate factor that accounts for the desired level of confidence in the control limits. This lower control limit helps in establishing boundaries for the process performance and indicates when the process is statistically out of control.

How is the centerline calculated in a P Chart?

The centerline in a P Chart is calculated by averaging the proportion of nonconforming units within the set of samples taken. This average proportion is then used as the target value around which the control limits are established to monitor the process variability and detect any potential shifts or trends in the proportion of nonconforming units over time.

What does it mean if a data point falls outside the control limits on a P Chart?

If a data point falls outside the control limits on a P Chart, it indicates that the process is out of statistical control and that there may be a special cause variation present in the process. This means that some unexpected or unusual factor has influenced the process, leading to a point that is statistically unlikely under normal conditions. It is important to investigate and identify the cause of the variation to improve the process and bring it back into control.

How can a P Chart be used to monitor process stability?

A P chart can be used to monitor process stability by tracking the proportion of nonconforming items in a sample over time. By plotting the proportion of nonconforming items on the chart, any shifts or trends in the data can be easily identified, indicating whether the process is stable or not. Outliers or patterns can signal potential issues that require further investigation and corrective action to maintain process stability.

What are some advantages of using a P Chart?

Some advantages of using a P Chart include its ability to monitor process stability over time, detect variation and trends in quality performance, provide a visual representation of data for easy interpretation, establish control limits for identifying when a process is out of control, and help in improving process control and decision-making by identifying areas for improvement based on data analysis.

How can a P Chart be interpreted to identify process improvements?

A P Chart can be interpreted to identify process improvements by analyzing the control limits and patterns of variation in the data. If data points consistently fall within the control limits and show random variation, it suggests that the process is stable and predictable. However, if there are points outside the control limits or non-random patterns, such as trends, cycles, or shifts, it indicates potential issues that need to be addressed for process improvement. By focusing on these out-of-control points and patterns, organizations can pinpoint areas for intervention and make necessary adjustments to enhance process performance and reliability.

Have something to share?

Who is Worksheeto?

At Worksheeto, we are committed to delivering an extensive and varied portfolio of superior quality worksheets, designed to address the educational demands of students, educators, and parents.

Comments